Introduction: Solving Key Challenges with Zinc Benzoate

In the competitive landscape of industrial manufacturing, formulation challenges like corrosion, microbial degradation, and UV instability can compromise product integrity and performance. Forward-thinking chemists and formulators are constantly seeking multifunctional additives that deliver reliable results without complicating production. This is where the strategic uses of Zinc Benzoate (CAS 553-72-0) become a critical advantage. This versatile compound is more than just a simple salt; it’s a powerful problem-solver engineered to enhance durability, extend shelf life, and protect material value across a range of demanding applications.

In-Depth Applications: How the Uses of Zinc Benzoate Drive Innovation

The true value of Zinc Benzoate is revealed in its practical application. It functions as a highly effective process additive that addresses specific weaknesses in formulations, turning potential product failures into performance successes.

Application in High-Performance Coatings

- Problem: Metal substrates are highly susceptible to rust and corrosion, while water-borne coatings are vulnerable to bacterial and fungal growth, leading to spoilage and foul odors.

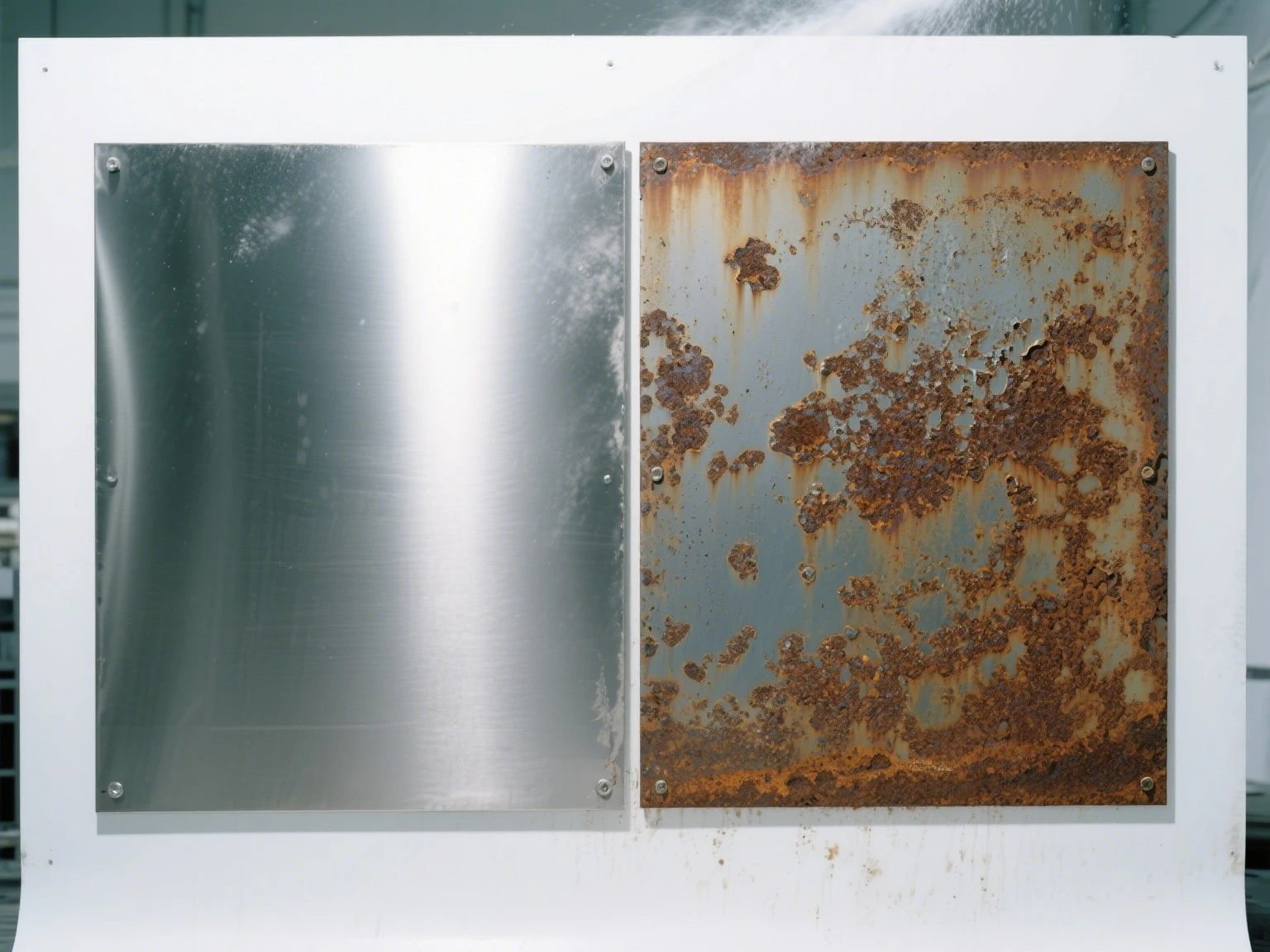

- Solution: Incorporating Zinc Benzoate into a coating formulation provides a dual-action defense. As an effective Zinc Benzoate preservative for coatings, it disrupts microbial metabolism. Simultaneously, it functions as a potent Zinc Benzoate as a corrosion inhibitor, passivating the metal surface to prevent oxidative damage.

- Result/Benefit: The coating exhibits a significantly longer in-can shelf life and provides superior, long-term corrosion protection for the underlying substrate. This extends the service life of the finished product, from industrial machinery to architectural steel, and aligns with stringent performance criteria detailed by bodies like the SSPC.

Application in Advanced Adhesives & Sealants

- Problem: Adhesives and sealants used in high-humidity or exterior environments can lose bond strength and integrity due to moisture ingress and microbial attack on organic components.

- Solution: The antimicrobial properties of Zinc Benzoate make it an ideal additive for protecting the polymer backbone of the adhesive from degradation. It helps maintain the formulation’s intended viscosity and cohesive strength, ensuring a stable and reliable bond.

- Result/Benefit: Formulators can create more robust adhesives and sealants that are resistant to environmental pressures. This results in stronger, more durable bonds for applications in construction, automotive assembly, and marine environments, reducing the risk of delamination and failure.

Advanced adhesive formulation benefiting from the antimicrobial properties of Zinc Benzoate to ensure a durable bond.

Application in Specialty Polymers & Plastics

- Problem: Plasticizers and other organic additives in PVC, polyolefins, and other polymers can be a food source for microbes, leading to discoloration, embrittlement, and surface degradation, especially in outdoor or hygienic applications.

- Solution: Zinc Benzoate acts as a preservative and stabilizer within the polymer matrix. It inhibits microbial growth on the surface and can contribute to scavenging acidic residues that form during processing or from environmental exposure, thereby protecting the polymer chain.

- Result/Benefit: This leads to plastic products with enhanced durability, improved aesthetic longevity, and better hygienic properties. This is one of the key uses of Zinc Benzoate in manufacturing everything from outdoor furniture and decking to flexible PVC tubing used in medical devices.

Partner with Us to Elevate Your Application

Understanding the diverse uses of Zinc Benzoate is the first step toward solving your most pressing formulation challenges. Our team is dedicated to helping you leverage its full potential to improve your products, from initial testing to full-scale production. We provide consistent, high-purity Zinc Benzoate backed by expert technical support.

Ready to see the difference Zinc Benzoate can make? [Contact Us] to request a sample or discuss your specific application with one of our industry specialists today.